|

Medium & LOW voltage power & CONTROL systems UL/ cUL

SKID MOUNT SOLUTIONS FOR

OIL & GAS, MINING, REMEDIATION, WATER & WASTE WATER SYSTEMS

|

.

OIL & GAS FIELD

CONTAINER PACKAGED SOLUTIONS

Skid Power Systems with Intagrated

Skid Control Systems

__

Walk Through

Video

Download Info PDF

-

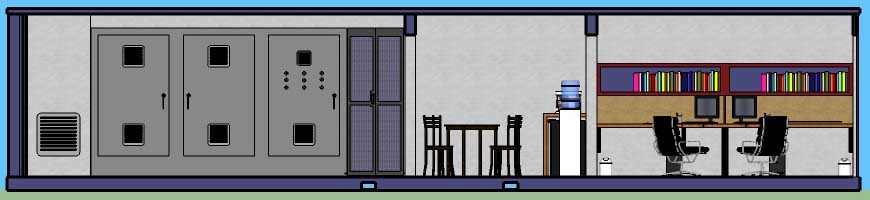

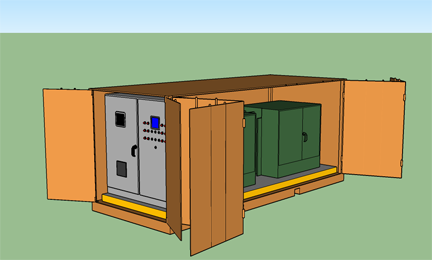

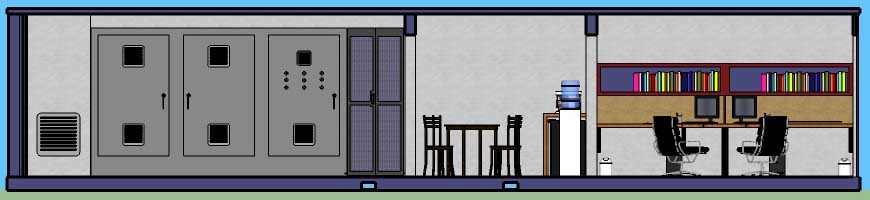

CONTAINER HOUSED OIL & GAS POWER & CONTROL SYSTEMS (PLC, PC-SCADA, MCC PDP, ETC) .

-

COMPLETELY FACTORY ENGINEERED, PRE-FABRICATED AND TESTED BEFORE SHIPMENT TO YOUR SPECIFICATIONS.

-

IN FACTORY PROCESS AND CONTROLS PRE-PROGRAMMED AND TESTED.

-

EXGTREME WEATHER LOCATIONS

-

Let ICI do the Engineering and Handle the Logistics, While you Manage Production

OPTIONS: ..................

-

POWER DISTRIBUTION

-

MOTOR(S) CONTROL

-

MOTOR SPEED CONTROL (VFD's) 380Vac to 4160 Vac +

-

PROCESS CONTROL (Plant & Well Automation & SCADA)

-

AGA GAS & OIL FLOW WITH ANALYTICAL MEASUREMENT AND DATA LOGGING

-

SCADA AND DATA SERVER , SQL, WONDERWARE, AB FT, OTHERS

-

PLC PROGRAMMING, AGA, HISTORIAN, BBL PRODUCTION & TRACKING

-

REMOTE SCADA- RF, SAT, CELL, CABLE, DSL, FIBER

-

HVAC

-

FIELD OFFICE SPACE

-

CUSTOM OPTIONS FOR YOUR APPLICATION

-

DESIGN & ENGINEERING SERVICES (Controls, Electrical, Mechanical, and Civil)

Custom Medium Voltage Skid Solutions For Pumping & Process Applications

Custom Container Packaged Power Skid Systems For Oil And Gas Pumping, And Processing. 360Vac to 4160Vac +

Custom Solutions For Specific Application.

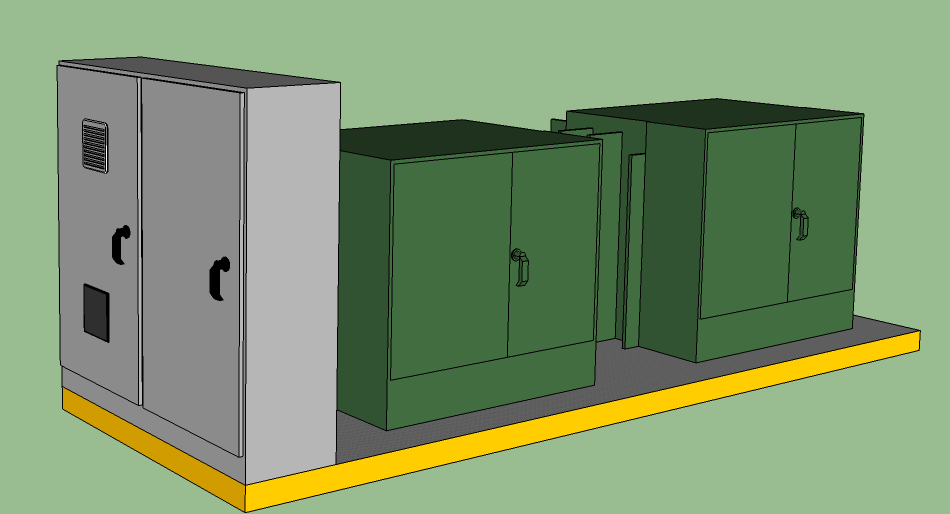

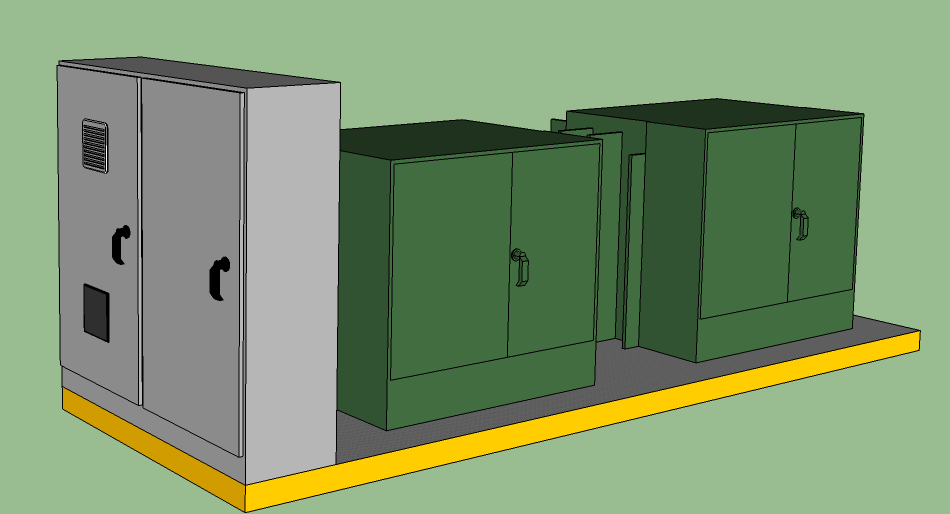

CUSTOM OUT-DOOR NEMA 3,3r 4, 4x RATED OPTIONS FOR SKID POWER AND PUMPING SOLUTIONS

MEDIUM VOLTAGE VFD MOTOR CONTROLS BETWEEN 25 - 700+ Hp

- CUSTOM BUILT TO YOUR SPECIFICATIONS

- UL AND cUL 508/698 LISTED CONTROLS, SKID POWER DESIGNED TO NEC, DOE, AND NFPA STANDARDS

- SHORT TURN AROUND TIME TO YOUR SPEC

- LOWER COST SOLUTION COMPARED TO MEDIUM VOLTAGE DRIVES

- TOTAL PACKAGE: POWER, CONTROLS, PUMPS AND MOTORS, SKID MOUNTED

- SCADA (CELL) READY WITH HISTORY, TREND, WEB ACCESS

- ENERGY EFFICIENT MEDIUM VOLTAGE MOTOR DRIVE PACKAGES

- MOTOR, PUMP, OR COMPRESSOR SKID MOUNTED WITH ALL INSTRUMENTS

- SHIP WORLD WIDE, FACTORY TESTED

- ALLEN BRADLEY, TOSHIBA, DRIVE, MOTORS AND CONTROLS.

- AMBIENT TEMPERATURES FROM -45DegC to +45DegC

- 360 - 4160 VOLTS 3 PHASE 50 - 60 Hz SERVICE YOUR MOTOR VOLTAGE

- INSTRUMENTATION & CONTROLS INCLUDES BUT NOT LIMITED TO:

- AGA GAS FLOW CALCS, HISTORY & REPORTING

- OIL AND BRINE BBL MEASUREMENT, HISTORY, & REPORTING

- SCADA: (RF, CELL, SATELLITE, FIBER, Other)

- PUMP OFF CONTROL

- PUMP RATE CONTROL

- FLOW RATE CONTROL

- GAS COMPRESSION

- LIQUID MOTIVATION ( BOOSTER PUMPS AND CRUDE TRANSPORTING )

- NATURAL GAS TRANSFER

- ALL SYSTEMS ENGINEERED AND BUILD TO NEC, UL, cUL, C1D1, C1D2, AND NFPA STANDARDS PER SPECIFIC APPLICATION.

|

NEMA3R SKID POWER SOLUTIONS

OUT DOOR GENERATOR, & PUMP CONTROL PACKAGE

Constant Pressure, Constant Level, VFD Driven

view

brochure view

brochure

Open Skid Mounted VFD Based Pumping Systems With Generator, ATS, Pre-Wired

And Tested Prior To Delivery, Any Size, With Multi Fuel Options. Quick Turn Around Time,

Fast Install And Start Up Time.

ALL SKIDS

- FAST TURN AROUND TIME ON ALL SKIDS

- CUSTOM ENGINEERED TO YOUR SPECIFICATIONS

- IN HOUSE ENGINEERING FOR STRUCTURAL, ELECTRICAL, CONTROLS, AND HYDRAULICS

- NATIONAL NAME BRAND SUB-COMPONENTS

- ON SITE START UP AND COMMISSIONING IN MOST COUNTRIES

- ON SITE EXTENDED SUPPORT IN MOST COUNTRIES

- CUSTOM ALGORITHMS TO INSURE OPTIMUM EQUIPMENT AND OPERATIONS EFFICIENCIES

- POWER SOURCES: ALL RANGES, 50-60Hz 1 AND 3 PHASE FOR

3 PHASE OUTPUT IN ANY VOLTAGE FROM 10-60 Hz

- OVER SPEED OPTIONS

- CUSTOM DESIGN MOTORS VOLTAGE AND POWER

- CUSTOM DESIGN FOR YOUR POWER RANGE AND NEEDS

Q&A

Q: Can I run a 3 phase motor if I don't have 3 phase power?

A: Yes, with a VFD, and proper sized transformers, we utilize VFD's to convert 1 phase power to 3 phase power necessary to run very large motors. Caution should be taken to be sure this is an engineered solution due to power losses.

Q: Can I get VFD's transformers, instruments and pumping equipment all packaged in one solution?

A: Yes we provide all components prefabricated, tested, and installed on a single or multiple skids as required to meet your needs providing you a single source supplier including start up commissioning.

Q: What is the advantage of a VFD over a Soft Start?

A: If you plan on starting and stopping your equipment more than once a day or if your peak performance could be anything less than 100% of your available speed or power or if you need to manage a very slow start up and or slow down, then the VFD is a far better choice than a soft start and you will receive the financial benefit that will exceed the additional cost in typically a year or less depending on your application.

Q: What is the advantage of working with an all inclusive manufacture such as ICI.

A: Integrated Controls Inc has provided UL listed power, pumping, pressure control, and process automation solutions for industry since their inception over 11 years ago. This level of experience makes ICI experts in taking your system or process concept and converting it into a highly effective, fully automated solution. Their experience working with both small and large process and pumping equipment affords them the level of expertise and synergy between providing a total equipment package and guaranteeing that the end results meet your high level of expectation.

Call 231-941-1030 to speak with an application engineer or go to “Contact” and fill out a request form to have an engineer contact you. (Click for Contact and request Info)

|

Integrated Controls, Inc. takes full

responsibility for the entire SKID,

from engineering, controls and pumps to instruments. 100% of the system is engineered,

built, and tested in-house prior to delivery. All you need

to do is provide power and external piping to & from. This single

source solution allows you to work exclusively with Integrated

Controls, Inc. throughout every stage for seamless and complete quality

control.

|

|

|

WHY

CHOOSE A SKID MOUNT SYSTEM FROM INTEGRATED CONTROLS, INC?

Integrated

Controls, Inc. is much more than an

UL controls facility, we have years of mechanical and fluid dynamics engineering experience.

For years, we have been solving pump related and fluid flow

issues and delivering quality and dependable process solutions. Because

we design, build, wire, program and test the pumping system, PLC controls, and instruments in house, we are able to deliver

to

you the highest quality turnkey product available on the market today. We offer you the best

of both worlds: cost savings and premium quality with exceptional turn around time.

A Few Reasons Why...

- Electrical, I&C, and mechanical in-house engineering

- Electrical and mechanical in-house assembly and testing

- In-house UL certified control panel fabrication facility

- In-house programming and testing

- In-house instrumentation and calibration

- By

combining all of the talents and equipment under one

roof,

we reduce the cost of manufacturing and insure

the

highest quality and

dependability in product delivery with

a faster turn around time.

- We can design and build the complete pumping package

the way you need it

with the brand and type of pumps, motors, and

controls

you request.

- Years of experience manufacturing and providing process control logic using VFD integrated solutions

RETURN TO TO

Standard Features

RETURN TO TOP

Options and Capabilities

- Sized

to suit applications and future needs

- Constant

level, pressure, or flow options are standard

- NEMA

1, 3R, 4, 4X, or 12 type enclosures

- Suction

and discharge pressure management

- Liquid

surge elimination

- Auto

chemical injection and management

- VFD

panel temperature management

- Bypass

starters for redundancy

- SCADA and advanced alarming

- Custom

designed to meet your requirements

- Advanced

fault diagnostics

- Intuitive

graphical display (GUI)

- Matched

drive and motor package with RTD and vibration monitoring

RETURN TO TOP

Applications

The

uses and applications for the skid mounted pumping system

are endless. Listed below are a few of the areas in which

our pumping systems have already been installed.

Call 231-941-1030 to speak with an application engineer or go to “Contact” and fill out a request form to have an engineer contact you. (Click for Contact and request Info)

RETURN TO TOP

|

|

![]()